Acoustic Roller Shutter

SilentRoll®

45/50dB

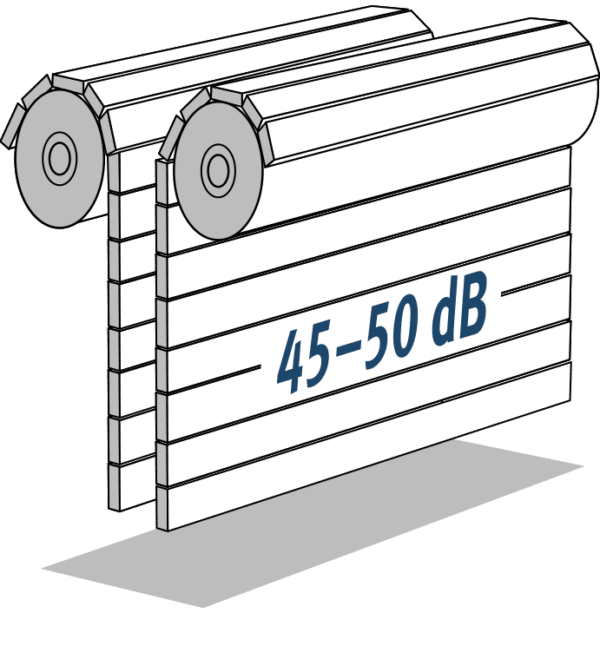

Dual-Layer Acoustic Roller Shutters (Rw 45-50dB)

Model Reference: SD-RSD45/50

SilentRoll® 45 & SilentRoll® 50 – High-Performance Acoustic Roller Shutters

For environments demanding maximum noise reduction, the SilentRoll® 45 and SilentRoll® 50 acoustic roller shutters offer industry-leading sound insulation, reducing noise transmission by up to 45dB and 50dB (Rw), respectively. These heavy-duty soundproof shutters are ideal for industrial sites, manufacturing plants, testing facilities, and high-security areas where superior acoustic performance is essential.

Built with a dual-layer galvanised steel construction, integrated soundproofing materials, and a two-barrel roller system, these shutters provide exceptional durability, strength, and acoustic control.

Key Benefits:

✔ Industry-leading noise reduction of up to 50dB for high-noise environments.

✔ Dual-layer galvanised steel with integrated acoustic dampening.

✔ Two-barrel system for enhanced structural stability and performance.

✔ Heavy-duty electric operation with manual override for emergency access.

✔ Precision-engineered seals to minimise sound leakage and enhance insulation.

Whether you need high-performance acoustic control for industrial, commercial, or specialist applications, the SilentRoll® 45 & 50 deliver unmatched soundproofing, security, and reliability.

✅ Enhanced Acoustic Insulation

- Rw 45dB – 50dB sound reduction (ISO 140-3 tested).

- Dual-layer roller shutter system with a minimum 645mm air gap for optimal noise control.

- 1.25mm thick hot-galvanized steel panels, filled with acoustic-grade mineral wool.

- Double-sealed lintel system to minimize airborne sound leakage.

- Side guides with integrated sealing strips for superior noise reduction.

- Additional absorption lining (SilentRoll® 50 only), featuring perforated steel panels and mineral fiber damping to further enhance sound insulation.

✅ Heavy-Duty Construction & Safety Features

- Two independent roller barrels made of pre-coated steel for enhanced stability and durability.

- Pre-galvanized steel bearing brackets for long-term reliability.

- Integrated hollow-chamber damping within the side guides for added soundproofing.

- Impact-resistant T-steel bottom rails with an IP65-rated electrical safety edge for door movement monitoring.

- Safety monitoring electronics with optical fault indication.

- Drive chains with a 6x safety factor against breakage (for chain-driven versions).

- Protective covers for chain-driven models installed below 2.5m.

✅ Powerful Motor System

- Two synchronized electric drives (60% duty cycle, IP54-rated).

- 3~400V AC / 16A power connection, 50Hz.

- Direct-coupled worm gear system with spring-applied brake for precise control and emergency stopping.

- Built-in anti-fall safety system (EN 12604 compliant).

- Manual override crank with safety interlock for backup operation.

✅ User-Friendly Control Unit

- IP54-rated control panel in a robust plastic casing.

- Up-Stop-Down keypad integrated into the control box.

- Dead man's control (self-hold open function available for doors over 2.5m height).

- 1m pre-wired cable with CEE plug for quick installation.

- Optional lockable main switch for enhanced security.

Installation & Operational Considerations

🚧 Maximizing Acoustic Performance

To achieve the highest soundproofing efficiency, building acoustics must complement the shutter's performance:

- Walls and surrounding structures should have an Rw rating matching or exceeding the door.

- Floor sealing should be acoustically decoupled (e.g., using an elastic joint instead of continuous screeds).

⚡ Power & Safety Requirements

- Requires 400V / 16A three-phase power supply with a CEE socket near the control panel.

- Optional emergency stop switch available upon request.

🛠 Surface Wear Disclaimer

- Normal operation may cause minor surface wear on the shutter and guide rails.

- Degree of wear depends on frequency of use, weight load, and environmental factors.

- This does not impact functionality and is considered a standard characteristic of rolling shutter systems.